Company News

-

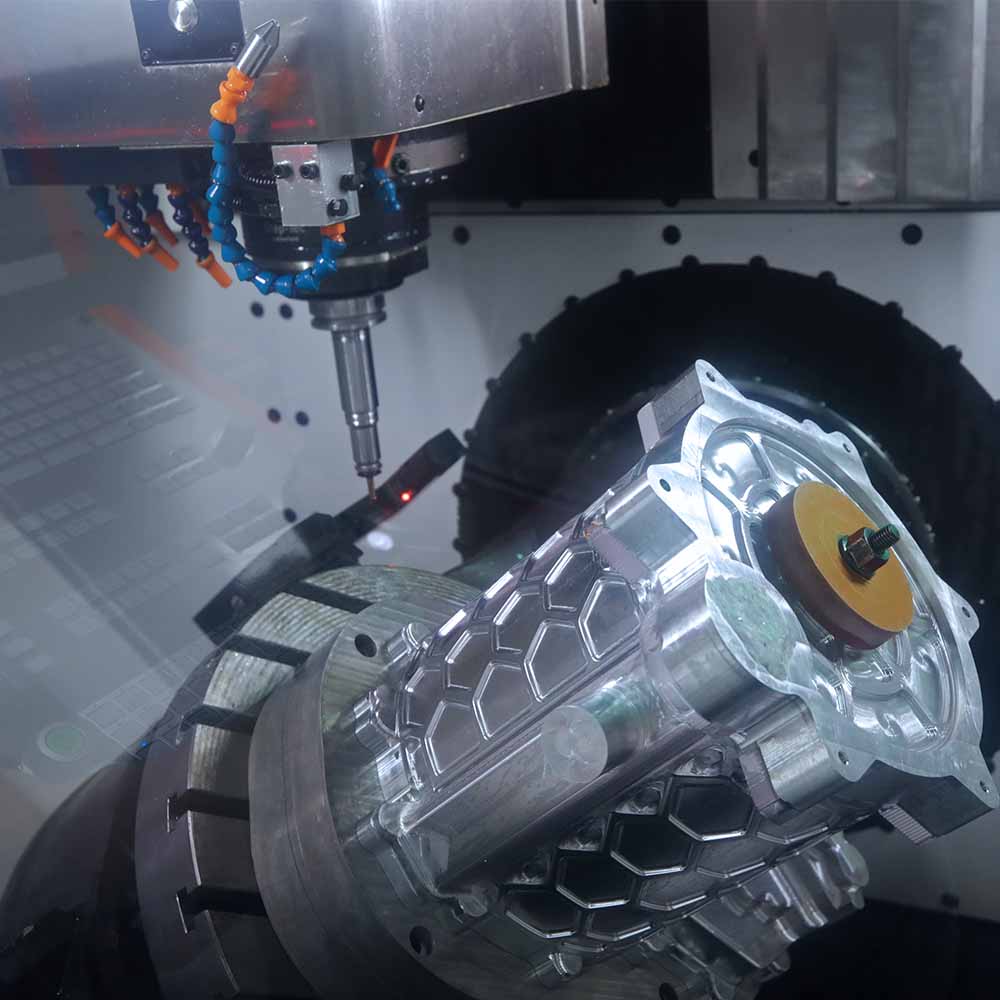

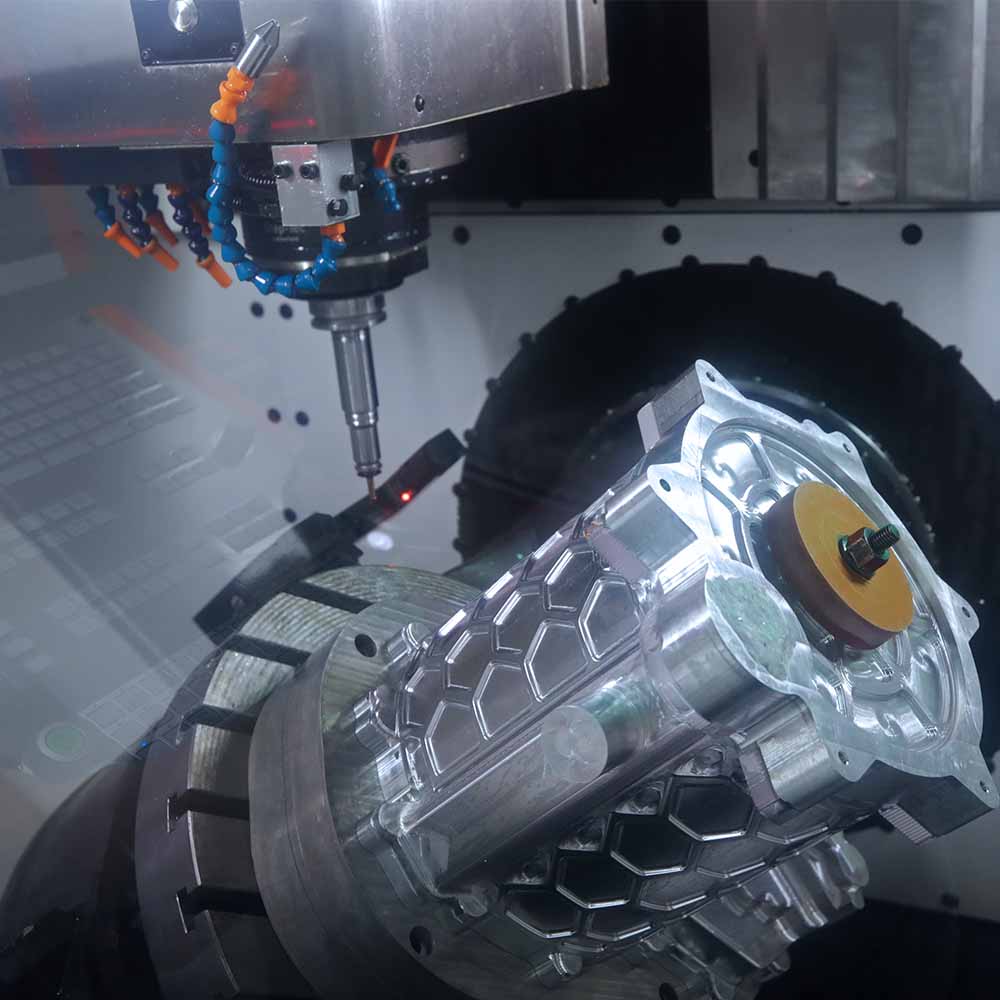

What is CNC Machining? 3 Axis | 4 Axis | 5 Axis

CNC (computer numerical control) machining is a process in manufacturing where programmed computer software directs the motions of plant machinery and tools. The application can be used to automate a range of manufacturing techniques such as milling, water jet cutting, and laser cutting material...Read more -

What are CNC machining services?

Over the past few years, CNC machining services have become a vital part of the modern manufacturing world. They offer a wide range of benefits, including efficiency, scalability . But you know what is CNC machining, exactly? What are the various types? And more so, what benefits does it offer? ...Read more -

How to Choose a CNC Custom Machining Service:

Based on variations in market conditions, consumers’ personalized needs are very different, and demand is small, so CNC processing tends towards custom processing. Therefore, modern CNC custom machining has adapted to a variety and small batches of products by developing machines that reduc...Read more -

CNC Machining vs Injection Molding

Humans produce hundreds of millions of plastic products every year. This adaptable material can be formed into finished products by a variety of methods. Two popular methods are injection molding and CNC machining, but do you understand the different advantages of each? This article will help you...Read more -

3 Lightweight Metals and Their Key Benefits

Steel is the most widely used metal in the world today and offers a great balance of material properties at a good cost. But when steel, at a density of 7.8g/cm³, is too heavy for the application, product designers must turn to one of the lighter materials available. While many plastics are avail...Read more -

What is Anodized Aluminum?

Anodizing is among the most common post-processing operations performed on aluminum parts. It is an electrochemical process that involves immersing an aluminum part in a series of tanks, converting the aluminum surface into a durable and corrosion-resistant finish. To determine whether anodizing ...Read more -

Do you know the processing methods of the five-axis machining center?

The five-axis machining center is the abbreviation of the five-axis linkage CNC machine tool machining center. This equipment is a machine tool with at least five coordinate axes, which are processed in coordinated motion under the control of the computer numerical control system. Five-axis linka...Read more -

Precision parts processing process

Precision mechanical parts manufacturing production process, under the premise of ensuring the quality of the parts, the process of developing a good comprehensive technical and economic benefits, reasonable and feasible process plan is called the process design of the parts. The process of par...Read more -

CNC Machining Precision Optical Components: An Overview

One of the key technologies contributing to the impressive growth of this industry in recent years is CNC machining. Computer numerical control (CNC) machining relies on computer code to convert 3D CAD models into machined parts, making them highly accurate in fabricating optical communication p...Read more -

What is the Strength-to-Weight Ratio, and Why Does it Matter to Engineers?

Engineers must be able to accurately assess and analyze a material’s various properties before incorporating it into any application. The strength of a material is important to consider, but so is the weight, as this affects both the carrying capacity and efficiency of the design. The strength-to...Read more -

How can CNC machining improve machining accuracy and efficiency?

Under the conditions of rigidity, a larger depth of cut is used for roughing to reduce the number of passes and improve the productivity of the workpiece; for finishing, a smaller depth of cut is generally used to obtain higher surface...Read more