News

-

CNC milling process for typically thin-walled parts

Thin-walled parts are widely used in various industrial sectors, which have the characteristics of light weight, material saving and compact structure. However, thin-walled parts are difficult to process. This paper analyzes the technical problems that exist in the processing of thin-walled parts...Read more -

CNC Machining Precision Optical Components: An Overview

One of the key technologies contributing to the impressive growth of this industry in recent years is CNC machining. Computer numerical control (CNC) machining relies on computer code to convert 3D CAD models into machined parts, making them highly accurate in fabricating optical communication p...Read more -

What is Deburring, and How Does it Improve Your Metal Parts?

Deburring is an easily overlooked step that can greatly impact the finished part quality. Its importance ranges from being a good practice to an essential step depending on how the deburred parts will be used. The Importance of Deburring Deburring is sometimes viewed as an unnecessary extra step,...Read more -

What is the Strength-to-Weight Ratio, and Why Does it Matter to Engineers?

Engineers must be able to accurately assess and analyze a material’s various properties before incorporating it into any application. The strength of a material is important to consider, but so is the weight, as this affects both the carrying capacity and efficiency of the design. The strength-to...Read more -

Cast Iron vs. Steel: What Are Their Advantages and Disadvantages?

Both steel and cast iron are popular metals, but they are often used very differently. The key factor distinguishing one from the other is how much carbon each contains, and to a lesser extent, how much silicon. While this may seem like a subtle distinction, it has major implications for the prop...Read more -

CNC Machining for the Energy Industry

Humans’ energy needs were modest before the industrial revolution. For example, we were happy to utilize energy from the sun for heat, horses for transportation, the power of the wind to sail around the globe, and water to drive simple machines that grind grains. Everyth...Read more -

Machining Titanium vs. Stainless Steel How to choose the correct processing material

Machining is an essential process for creating metal parts and components across many industries, from aerospace to automotive. Choosing the right machining material is an important decision that needs careful consideration. This article explores the advantages and disadvantages of using titanium...Read more -

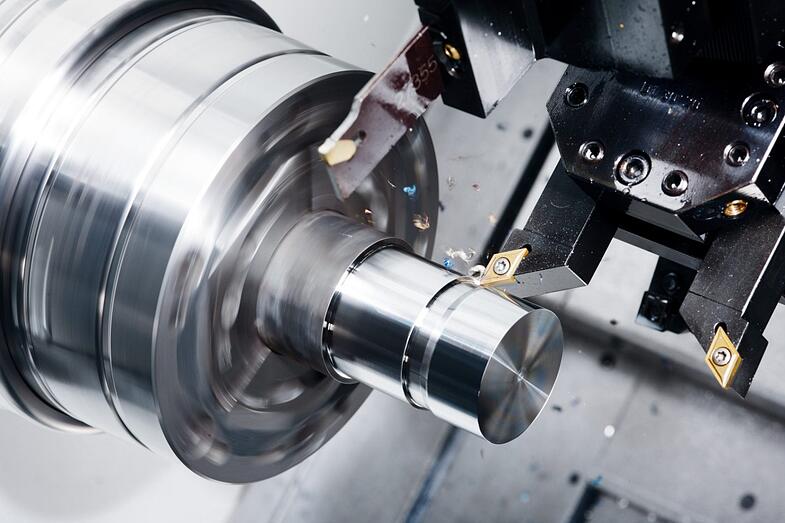

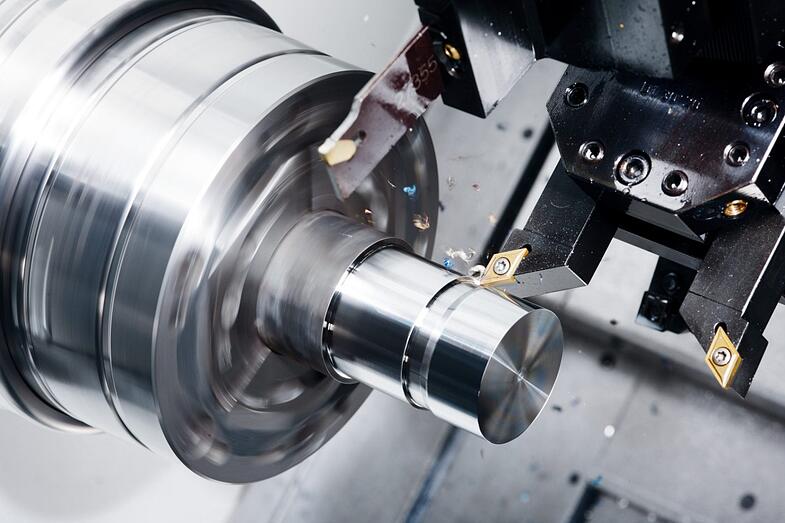

What is a CNC Lathe?

Lathes are incredibly versatile machines. They’ve been used in one form or another for thousands of years to make tools, furniture, parts, and more. How a CNC Lathe Works There is a wide range of equipment available in a machine shop, but CNC lathes create unique shapes that can’t be easily m...Read more -

5 Important Design Considerations for CNC Turned Parts

CNC (computer numerical controlled) machines are used to create turned parts with a very high degree of accuracy. The machines are programmed to follow a set of instructions that tell them how to cut and shape the material. This process ensures that each part is exactly ...Read more -

What is Machinability?

Machinability is a material property that describes the relative ease with which a material can be machined. While it’s most often used for metals, it applies to any machinable material. A material with above-average machinability demonstrates a few important benefits during machining: Reduced to...Read more -

What is CNC Turning?

The first part of CNC turning is “CNC,” which stands for “computer numerical control” and is commonly associated with the automation of machining processes. “Turning” is the machining term for a process where the workpiece is rotated while a single-point cutting tool removes material to match the...Read more -

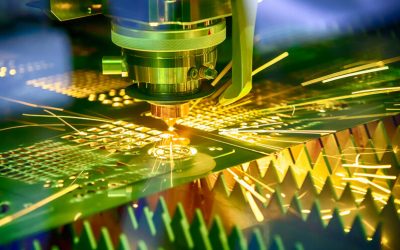

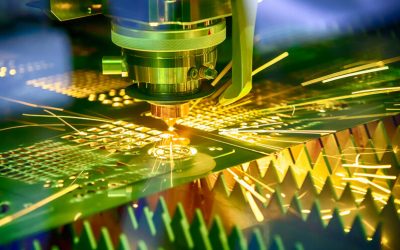

What is CNC Milling?

What is CNC Milling? CNC milling is a machining process that utilizes computerized controls to manage the movement and operation of multi-point rotary cutting tools. As the tools rotate and move across the surface of the workpiece, they slowly remove excess mater...Read more