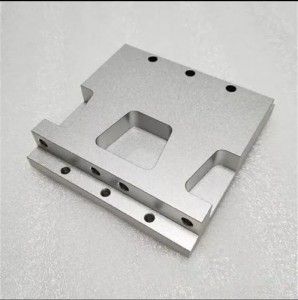

CNC milling, CNC turning CNC machining milling CNC machining turning stainless steel,metal parts

Product Description

CNC milling machine / CNC lathe / grinding machine / milling machine / lathe / wire cutting etc.

Aluminum alloy:

5052/6061/6063/2017/7075 ect.

Brass alloy:

3602/2604/H59/H62 ect.

Stainless steel alloy:

303/304/316/412 ect.

Carbon steel alloy:

carbon/ steel/die steel/etc.

We handle many other types of materials. If you need materials not listed above, please contact us.

blackened, polished, anodized, chrome-plated, zinc-plated, nickel-plated, pigmented

Hardness Tester、 Image measuring instrument、3D measuring instrument ect.

AutoCAD(DXF、DWG)、PDF、TIF、 IGS、UG、Solidworks ect.

The particularity of CNC machining customization

1. Custom tool steel parts generally have higher strength and integrity, as well as higher precision.

2. Compared to many other methods, the manufacture of custom machined parts using CNC machines is much faster.

3. Because CNC machining customization services maximize part detail, CNC machining customization is often manufactured for performance-critical industries.

4. Custom parts are non-standard or not available from common suppliers, some features of custom parts are not available on standard components.

5. Mechanical CNC machining workshops usually accept small batches, customized parts are usually produced for a specific end use, and can guarantee the production and delivery of quality requirements within the agreed time.

Not only can we do your product well, but we are also located in the Greater Bay Area in southern China. Our proximity to major shipping ports allows us to quickly get your product to you.

You can try your product right away in just a few steps

● Upload your CAD file to import multiple designs of different parts at the same time to generate a single quote. A detailed cost estimate will appear on the screen soon.

● After you confirm the purchase contract, you only need to pay the advance deposit, and we will produce for you.

● After our production is completed and passed the inspection by the quality department, we can pack and deliver the goods according to the customer's requirements.

The customer can choose the receiving method, or we can arrange the delivery until the customer receives the goods and is satisfied.