CNC Milling – Aluminum, Stainless Steel, Brass, Carbon Steel, etc. – Xinsheng

CNC Milling – Aluminum, Stainless Steel, Brass, Carbon Steel, etc. – Xinsheng Detail:

Product Description

CNC milling machine / CNC lathe / grinding machine / milling machine / lathe / wire cutting etc.

Aluminum alloy:

5052/6061/6063/2017/7075 ect.

Brass alloy:

3602/2604/H59/H62 ect.

Stainless steel alloy:

303/304/316/412 ect.

Carbon steel alloy:

carbon/ steel/die steel/etc.

We handle many other types of materials. If you need materials not listed above, please contact us.

Blackened, polished, anodized, chrome-plated, zinc-plated, nickel-plated, pigmented

Height gauge, tooth gauge, image measuring instrument, three-dimensional measuring instrument, etc.

AutoCAD(DXF、DWG)、PDF、TIF、 IGS、UG、Solidworks ect.

Turning and milling compound machining module

Milling/turning centers are designed for efficient one-piece machining in a single setup. With its MILL-TURN Machining module, hyper MILL ® CAM software provides the perfect integration of milling and turning strategies in a single user interface.

Combined milling/turning centers are very complex CNC machines because they link two different types of machining techniques. The advantage is that workpieces can be milled and turned on one machine and one setup. This means that even highly complex workpieces can be machined in one setup. Therefore, the combination of milling and turning is becoming more and more important in CNC programming.

All-in-one machining on CNC machines

Turn-milling has enormous potential when it comes to manufacturing a specific range of parts. For example, when a typical milled part has a rotationally symmetrical outer contour, there is no need to clamp the part again on a second machine, thanks to one machining operation. Manufacturing time is reduced and greater precision is achieved. So, in general, mill-turning makes the manufacturing process more cost-effective.

Features

● Single programming environment for turning and milling tasks

● Wide range of available turning and milling strategies for flexible programming of complex 5-axis tasks

● Shared tool database for turning, milling and drilling tools enables standardized tool management

● A post-processor adapted individually to machine, controller and part range generates NC code for turning and milling operations in one NC program

What’s Included in an Online Quote

Upload a 3D CAD file of your machined part and we’ll send you a manufacturing analysis and an interactive quote within a few hours. In your quote, you can modify materials and quantities and see price updates in real time. Plus, in your manufacturing analysis, you can assign threads with a single mouse click.

Each part quote includes: real-time, accurate pricing, manufacturing analytics

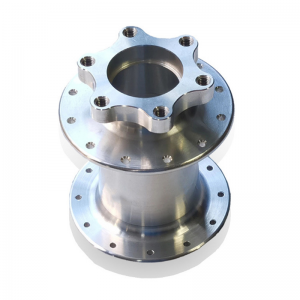

Product detail pictures:

Related Product Guide:

That has a sound business enterprise credit rating, exceptional after-sales provider and modern producing facilities, we now have earned an superb standing amongst our buyers across the world for CNC Milling – Aluminum, Stainless Steel, Brass, Carbon Steel, etc. – Xinsheng , The product will supply to all over the world, such as: Auckland, Mauritius, Accra, Products have been exported to Asia, Mid-east,European and Germany market. Our company has constantly been able to update the products performance and safety to meet the markets and strive to be top A on stable quality and sincere service. If you have the honor to do business with our company. we will definitely do our very best to support your business in China.

Perfect services, quality products and competitive prices, we have work many times, every time is delighted, wish continue to maintain!