Factory customized CNC processing aluminum parts, non-standard customized parts, milling parts

Product Description

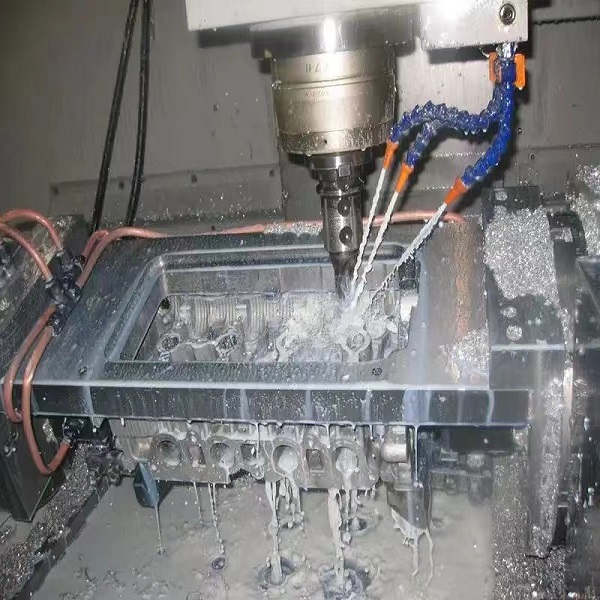

Processing equipment cnc milling machine / CNC lathe / grinding machine / milling machine / lathe / wire cutting etc.

Customizable material Aluminum alloy:

5052/6061/6063/6065/2017/7075 etc.

Brass Alloy:

3602/2604/H59/H62 etc.

Stainless Steel Alloys:

303/304/316/412/440C etc.

Carbon Steel Alloys:

Carbon steel/die steel, etc.

Customizable material Aluminum alloy:

5052/6061/6063/6065/2017/7075 etc.

Brass Alloy:

3602/2604/H59/H62 etc.

Stainless Steel Alloys:

303/304/316/412/440C etc.

Carbon Steel Alloys:

Carbon steel/die steel, etc.

We handle many other types of materials. If you need materials not listed above, please contact us.

Surface Treatment Blackened, Polished, Anodized, Chrome-plated, Zinc-plated, Nickel-plated, Tinted

Inspection Height gauge, tooth gauge, video measuring instrument, three-dimensional measuring instrument, etc.

File formats AutoCAD (DXF, DWG), PDF, TIF, IGS, UG, Solidworks, etc.

Customizable product requirements:

| Project name | Aluminum 6061, Stainless steel, brass, high precision metal parts |

| Processing equipment | CNC milling machine / CNC lathe / mill / milling machine / lathe / wire cutting, etc |

| Customizable material salufer: | aluminium: 5052 / 6061 / 6063 / 2017 / 7075, etc Copper Alloy: 3602 / 2604 / H59 / H62 et al stainless steel alloy: 303 / 304 / 316 / 412 et al steel : Carbon steel / die steel / etc We deal with many other types of materials. If the materials you need are not listed above, please contact us. |

| Surface treatment | blackened, polished, anodized, chrome plated, galvanized, nickel plated, colored |

| Drawing format | AutoCAD (DXF, DWG), PDF, TIF, etc. |

Quality Assurance:

High quality precision machining requires additional expertise and detailed adherence to specific blueprints in order to create exceptional products. Partnering with a reliable precision machining company is critical when seeking outstanding results. We offer a wide range of precision machining services, including precision turning, milling and EDM to meet your quality requirements.

From prototype to production, from 1 to 10,000 pieces, we offer fast turnaround CNC machining for your custom metal and plastic parts with as little as 3-day delivery

We can produce high precision complex parts with dimensional tolerances of ±0.01mm, geometric tolerances of 0.01mm, minimum machine radii of R0.1mm, and machined surface roughness of Ra0.2μm. We also often challenge optical parts with precise details.

CNC milling

With the rapid development of science and technology, society on the structure of mechanical products, performance, accuracy, efficiency and variety of requirements are increasingly high, the proportion of single-piece and small and medium-lot products is increasing. Traditional general-purpose, special machine tools and process equipment have not been well adapted to the requirements of high-quality, high-efficiency, diversified processing.

CNC machine tools as a combination of electronic information technology and traditional machining technology, a combination of modern precision machinery, computers, communications, hydraulic pneumatic, optoelectronics and other multidisciplinary technology as a whole, effectively solving the complex, precise, small batch of variable parts processing problems, to meet the high quality, high efficiency and multi-species, small batch of flexible production requirements, to adapt to the needs of a variety of mechanical products rapidly updated It represents the trend and trend of today's machining technology.

CNC milling parts

What is your delivery time?

In fact, there is no standard delivery time.We will schedule production according to the current workload. Once your buy order is received, documentation is complete, and materials are ready, we will give prompt feedback on the exact delivery time, which typically ranges from 3 business days to several weeks, depending on the complexity of the part and quantity of parts ordered.

FQA

Our prices are subject to change depending on supply and other market factors. We will send you an updated price list after your company contact us for further information.

Yes, we require all international orders to have an ongoing minimum order quantity. If you are looking to resell but in much smaller quantities, we recommend you check out our website.