CNC milling CNC machining High Precision Custom Milling Turn CNC Turned Metal Parts

Product Description

cnc fabrication,cnc lathe machining,cnc lathe machining parts,cnc machined component,cnc machining milling

Mechanical products, machining, CNC milling, CNC lathe parts, metal parts manufacturing

Material: Al6061

Surface treatment: natural color anodized

Testing tools or equipment: three-coordinate measuring instrument, needle gauge, screw gauge

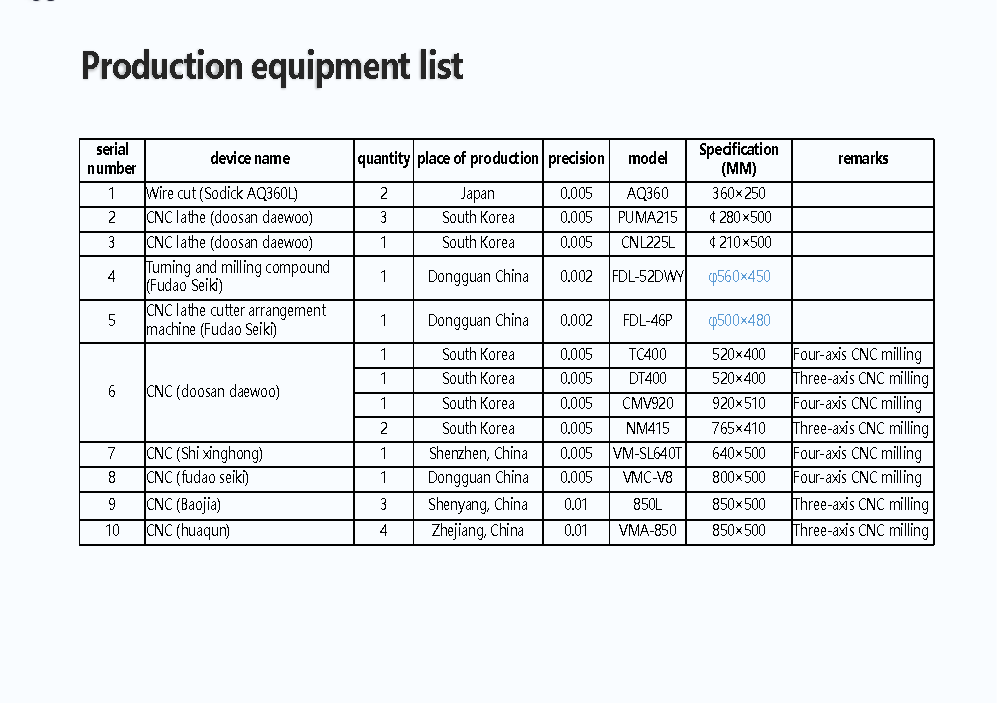

Processing equipment: CNC milling machine processing

Product specifications; customized according to customer requirements

Processing characteristics; the product requires a flatness of 0.05mm and no scratches on the surface

| Title |

| Processing equipment Aluminum 6061, stainless steel, brass, high precision metal parts |

| Customizable material cnc milling machine / CNC lathe / grinding machine / milling machine / lathe / wire cutting etc. |

| Aluminum alloy: |

| 5052/6061/6063/2017/7075 etc. |

| Brass Alloy: |

| 3602/2604/H59/H62 etc. |

| Stainless steel alloy: |

| 303/304/316/412 etc. |

| Steel Alloy: |

| carbon steel/die steel/etc. |

| Surface Treatment We process many other types of materials. If the material you need is not listed above, please contact us. |

| Inspection Blackened, polished, anodized, chrome-plated, zinc-plated, nickel-plated, colored |

| File format Hardness tester, image measuring instrument, three-dimensional measuring instrument, etc. |

Air transport Shipping

ABOUT US

Shenzhen Xinsheng Precision Hardware Machinery Co., Ltd. is a professional manufacturer of customized precision parts. The company has more than 50 technicians who are engaged in the production and manufacturing of precision parts. They have more than 10 years of overseas experience in manufacturing precision parts and have nearly 60 precision parts. Manufacturing machinery and equipment, as well as advanced Swiss-imported testing equipment and professional technical inspectors, make a trustworthy manufacturing enterprise.

CNC is an excellent technique for making low-volume unit prototypes,

product components, or bridge-to-market units of end parts.

CNC Processing Workshop

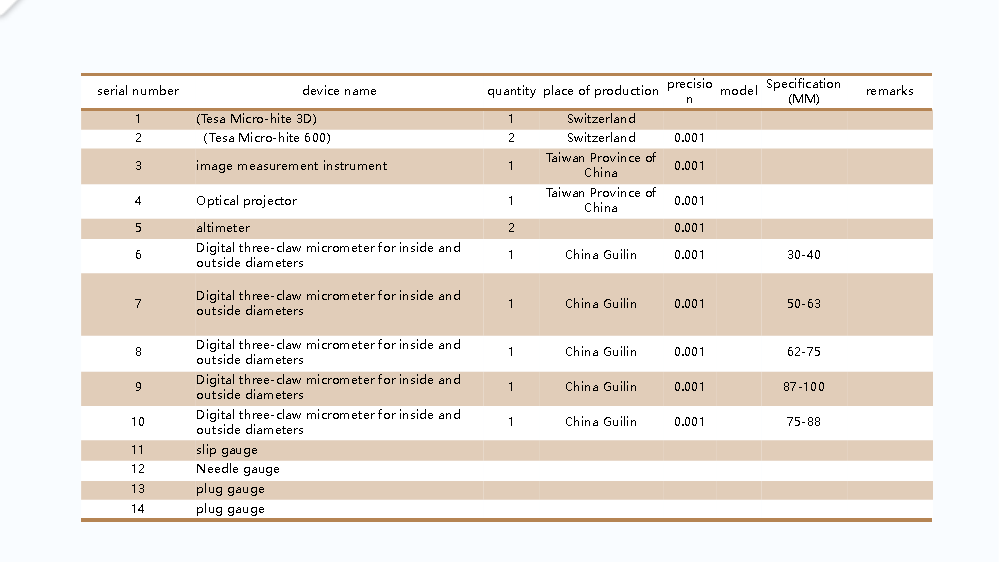

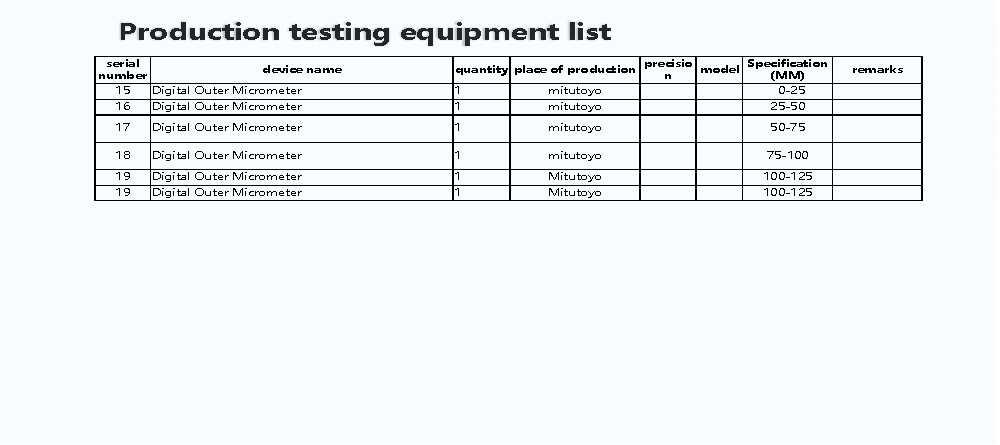

Quality Inspection Department

Slow Silk

Product Description

| Project name | Aluminum 6061, Stainless steel, brass, high precision metal parts |

| Processing equipment | CNC milling machine / CNC lathe / mill / milling machine / lathe / wire cutting, etc |

| Customizable material salufer: | aluminium: 5052 / 6061 / 6063 / 2017 / 7075, etc |

| Copper Alloy: | |

| 3602 / 2604 / H59 / H62 et al | |

| stainless steel alloy: | |

| 303 / 304 / 316 / 412 et al | |

| steel : | |

| Carbon steel / die steel / etc 222 | |

| We deal with many other types of materials. If the materials you need are not listed above, please contact us. | |

| Surface treatment | blackened, polished, anodized, chrome plated, galvanized, nickel plated, colored |

| Check | Altimeter, hardness meter, image meter, 3 D meter, etc |

| file formats | Height meter, hardness meter, image measuring meter, 3 D measuring instrument, etc |

| Drawing format | AutoCAD (DXF, DWG), PDF, TIF, etc. |

Production testing equipment list

CNC machining is excellent for quick prototyping, rapid testing and shortening product development cycles. In only a matter of hours, CNC can accelerate you from digitized CAD data to fully-functional prototypes.

- Aerospace and aircraft

- Automotive

- Commercial

- Electronics

- Industrial and OEM

- Maintenance

- Medical

- Technology and security

- Telecommunications

- Transportation

1. Our company specializes in non-standard, processing with drawings and samples and is not available in stock. Please know

2. The picture and price of this link are not the product price. Please consult the customer for a quotation and then check it. If you purchase without prior instructions, it will be an invalid order and will not be delivered. Thank you for your cooperation.

3. If customer service is unavailable, you can leave a message on the phone number and we will contact you later

4. If we do not customize according to the customer's drawings, we will replace them for free and bear the round-trip freight

5.2 days of sampling, 5 days of small batch trial production, fast delivery

6. If the product exceeds the drawing tolerance, it will be replaced free of charge, including freight

Yes, we are the production of automation equipment non-standard parts; High-precision parts; Precision fixtures; and all kinds of metal parts.

2What processing equipment do you have?

- CNC machining center;

- Walking wire;

- Electric spark;

- Numerical control car;

- Precision grinder and other equipment and supporting large gantry CNC, gantry grinding, gantry milling.

3. What services/products do you offer?

- From mold design, mold making, machining, fabrication, welding, surface treatment, assembly, packing to shipping.

- Automotive parts, bicycle parts, motorcycle parts, scooter parts, racing parts, audio products, medical equipment parts, electronic instruments parts, kitchen and bathroom products and other hardware parts.

- Iron/stainless steel/aluminum/titanium/brass/bronze/steel alloys/hardened parts/any kind of precision parts you need.

- Automatic lathe turning parts, milling parts, bending parts, welding parts, stamping parts. All kinds of hardware can be customized here.

4. How can I make sure my design is safe?

We won't leak any pictures or videos of the customers' products without approval. We can sign

NDA (none disclosure agreement) if needed.

5. How can I get a quote?

You can email us or inquiry below with your design or idea and let us know the material,

tolerance, quantity and surface finish you need, and we will send you a free quote for your consideration;

6. What file format would you prefer?

STEPS: ICES, DWG, DXF, STP, STL are preferred. A PDF will be needed for critical dimension making;

7. Why choose our company

- Full quality inspection before shipping;

Timely and professional communication;

Evaluate the feasibility of the idea/design.

- Working harder and more flexibly on customers' requests.

- 99.5% Customer Satisfaction

8. What are your Shipping Methods?

- Ocean Direct Shipping (Door to Door service) ;

- Truck/Railway shipping (for some countries)

- Air freight;

Ocean Freight

9. How can I get a sample for testing?

We will offer free or charged samples, depending on the products.

10 Materials to be provided by customers

Usually, 2D (format: DWG/DXF, etc.) drawings and 3D (STP/ICS, etc.) drawings need to be provided to the customer service so that we can accurately quote and process

11. Can it be processed without drawing?

We mainly undertake the processing business with drawings. For customers who do not know much about drawing, we need customers to provide detailed sketches, indicating detailed functional and dimensional requirements. We will provide design schemes, drawings, and processes after confirming with customers

12. Is processing cheaper than others?

We adhere to the principle of "one cent, one price, a good". The price cannot be guaranteed to be lower, but we do better in terms of quality, delivery time and service. Urgent orders: special personnel follow up from scheduling to production, 2 days for small batch trial production and 3 days for shipment

13. What is the processing capacity?

We have professional engineers, excellent technicians, and advanced processing equipment: CNC customization, 20 years of focus on precision hardware, CNC machining center, 33 CNC milling machines, 8 automatic lathes

FQA

Our prices are subject to change depending on supply and other market factors. We will send you an updated price list after your company contact us for further information.

Yes, we require all international orders to have an ongoing minimum order quantity. If you are looking to resell but in much smaller quantities, we recommend you check out our website.