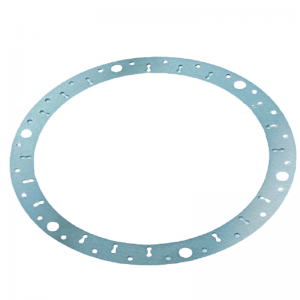

CNC precision machining CNC turning Custom fabrication Aluminum, stainless steel, turning, CNC machining

Product Description

Processing equipment cnc milling machine / CNC lathe / grinding machine / milling machine / lathe / wire cutting etc.

Customizable material Aluminum alloy:

5052/6061/6063/6065/2017/7075 etc.

Brass Alloy:

3602/2604/H59/H62 etc.

Stainless Steel Alloys:

303/304/316/412/440C etc.

Carbon Steel Alloys:

Carbon steel/die steel, etc.

We handle many other types of materials. If you need materials not listed above, please contact us.

Surface Treatment Blackened, Polished, Anodized, Chrome-plated, Zinc-plated, Nickel-plated, Tinted

Inspection Height gauge, tooth gauge, video measuring instrument, three-dimensional measuring instrument, etc.

File formats AutoCAD (DXF, DWG), PDF, TIF, IGS, UG, Solidworks, etc.

Features

CNC turning is an automated work mode that greatly improves work efficiency. CNC turning generally has lower error rates and higher part quality than manual turning in the automated process.

CNC turning is perfectly suitable for the production of small and medium parts on a scale of 50-1000.

CNC turning is an automated work mode, which greatly improves work efficiency and saves labor costs, thereby reducing the overall cost of parts

Application areas; semiconductor industry, medical equipment, automation equipment, precision fixtures, optical industry, SMT equipment, automobiles, molds, shipbuilding, aerospace, construction machinery and other fields

What's Included in an Online Quote

Upload a 3D CAD file of your machined part and we'll send you a manufacturing analysis and an interactive quote within a few hours. In your quote, you can modify materials and quantities and see price updates in real time. Plus, in your manufacturing analysis, you can assign threads with a single mouse click.

Each part quote includes: real-time, accurate pricing, manufacturing analytics